|

|

||||||||

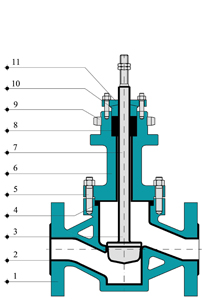

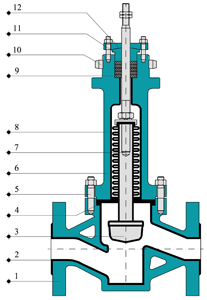

| 1 | Body | WCB | LCB | WC9 | 1 | Body | CF8 | CF8M | CF3M |

| 2 | Lining | F46 / F4 | 2 | Lining | F46 / F4 | ||||

| 3 | Seat | 304 | 304 | 304 | 3 | Seat | 304 | 316 | 316L |

| 4 | Shim | PTFE | 4 | Shim | PTFE | ||||

| 5 | Screw nu | 304 | 304 | 304 | 5 | Screw nu | 304 | 316 | 316L |

| 6 | Valve cover | WCB | LCB | WC9 | 6 | Valve cover | CF8 | CF8M | CF3M |

| 7 | Valve stem | 304 | 304 | 304 | 7 | Valve stem | 304 | 316 | 316L |

| 8 | Packing | PTFE | 8 | Corrugated pipe | PTFE | ||||

| 9 | Lock nut | 304 | 304 | 304 | 9 | Packing | PTFE | ||

| 10 | Pressing ring | WCB | LCB | WC9 | 10 | Lock nut | 304 | 316 | 316L |

| 11 | Plate | WCB | LCB | WC9 | 11 | Pressing ring | CF8 | CF8M | CF3M |

| 12 | Plate | CF8 | CF8M | CF3M | |||||

| DN(mm) (in) |

20 3/4 |

25 1 |

32 1-1/4 |

40 1-1/2 |

50 2 |

65 2-1/2 |

80 3 |

100 4 |

125 5 |

150 6 |

|

| (KV) Flow coefficient | 5 | 10 | 16 | 25 | 38 | 63 | 80 | 120 | 220 | 300 | |

| DN (in) | Travel | Optional flow coefficient CV (★ Standard type ● Recommend) | |||||||||

| 20 3/4 | 16 mm | ★ | |||||||||

| 25 1 | 25 mm | ★ | |||||||||

| 32 1-1/4 | ● | ★ | |||||||||

| 40 1-1/2 | ● | ● | ★ | ||||||||

| 50 2 | 40 mm | ● | ★ | ||||||||

| 65 2-1/2 | ● | ★ | |||||||||

| 80 3 | ● | ● | ★ | ||||||||

| 100 4 | 60 mm | ● | ★ | ||||||||

| 125 5 | ● | ★ | |||||||||

| 150 6 | ● | ● | ★ | ||||||||

| Pneumatic actuator | HA/B-23 | HA/B-34 | HA/B-45 | ||||||||

| 350 cm2 | 560 cm2 | 900 cm2 | |||||||||

| Mode of action | Spring range | Allowable differential pressure (Mpa) | |||||||||

| Gas opening | 20-100Kpa | 1.16 | 0.7 | 0.44 | 0.28 | 0.18 | 0.17 | 0.11 | 0.07 | 0.07 | 0.05 |

| 40-200Kpa | 3.34 | 2.14 | 1.31 | 0.84 | 0.53 | 0.51 | 0.33 | 0.21 | 0.22 | 0.15 | |

| 80-240Kpa | 6.4 | 4.99 | 3.05 | 1.95 | 1.25 | 1.18 | 0.78 | 0.5 | 0.51 | 0.36 | |

| Gas off | 20-100Kpa | 2.23 | 2.14 | 0.87 | 0.56 | 0.35 | 0.34 | 0.22 | 0.14 | 0.15 | 0.1 |

| 40-200Kpa | 6.4 | 6.4 | 5.86 | 3.64 | 2.3 | 2.21 | 1.43 | 0.91 | 0.95 | 0.66 | |

| 80-240Kpa | 6.4 | 6.4 | 6.4 | 5.04 | 3.18 | 3.06 | 1.98 | 1.26 | 1.32 | 0.92 | |

| Electric actuator | Allowable differential pressure (Mpa) | ||||||||||

| Thrust(N) | 800 | 2.38 | 1.52 | ||||||||

| 2000 | 4.77 | 3.05 | 1.86 | 1.19 | 0.76 | ||||||

| 3000 | 2.79 | 1.79 | 1.14 | ||||||||

| 5000 | 4.66 | 2.98 | 1.91 | 1.13 | 0.6 | 0.47 | |||||

| 6500 | 1.35 | 0.8 | 0.57 | 0.39 | 0.26 | ||||||

| 10000 | 0.61 | 0.42 | |||||||||